Large-bore size

You are here:

Tech - Con Czech Republic > Products > Pneumatics > Movement > Shock Absorbers > Non-adjustable shock absorber category > Large-bore size

Overwiev

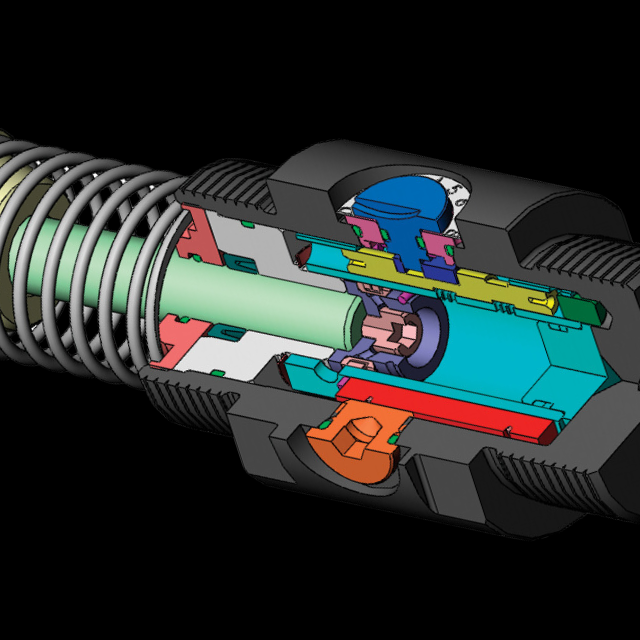

We offer shock absorbers for absorbing the energy that is generated during a movement. These products work by converting kinetic energy to thermal energy. The use of industrial shock absorbers ensures longer machine life, higher operating speed, improved production quality, safer machinery operation, and thanks to these increased productivities, and lower maintenance costs.

We use different formulas to help you choose the right product for a wide range of applications. Sizing software is also available for this task.

Features

We offer Heavy Duty Series large-bore hydraulic shock absorbers that protect equipment from large impacts in applications such as automated storage and retrieval systems, as well as overhead bridge and trolley cranes. They are available in a wide variety of stroke lengths and damping characteristics to increase equipment life and meet stringent deceleration requirements.

- Non-adjustable type

- Size from 90 mm to 200 mm

- Stroke between 50 mm and 1830 mm

- The maximum energy per cycle is between 3200 Nm/c and 329300 Nm/c

- The maximum shock force is between 16460 N and 355900 N

We offer Heavy Duty Series large-bore hydraulic shock absorbers custom-orifice holes design that accommodates specified damping requirements. Computer-generated output performance simulation is used to optimize the orifice configuration. Available in standard bore dimensions of up to 125mm and 156mm with strokes over 1525mm.

- Non-adjustable type

- Size are 215 mm and 275 mm

- Stroke between 100 mm and 1200 mm

- The maximum energy per cycle is between 46700 Nm/c and 898200 Nm/c

- The maximum shock force is between 410000 N and 900000 N

Downloads

News

Enidine Adjustable Miniature Shock Absorber

Miniature Shock Absorbers for Limited Space Applications Enidine Adjustable Small Bore Hydraulic Series miniature shock absorbers offer the most flexible…

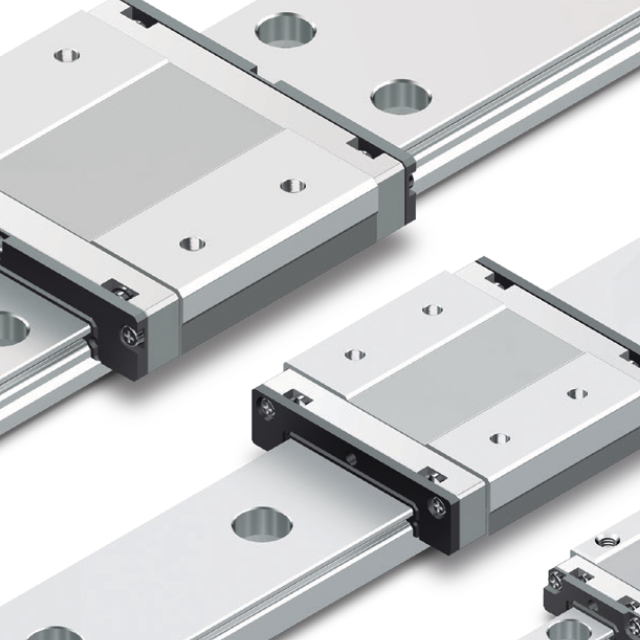

THK High Temperature LM Guide RSX-M1

Miniature LM Guide for use in temperatures as high as 150°C The Model RSX-M1 utilizes unique material, lubrication, and heat…

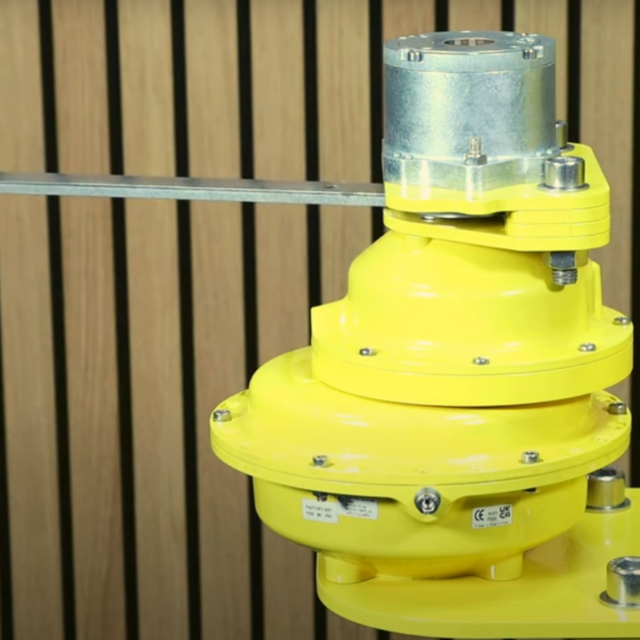

Kinetrol D-Line Damped Manual Fail-Safe

The D-Line damped manual fail-safe uses Kinetrol’s highly reliable, low stress, clock type spring linked to a torque multiplier to…

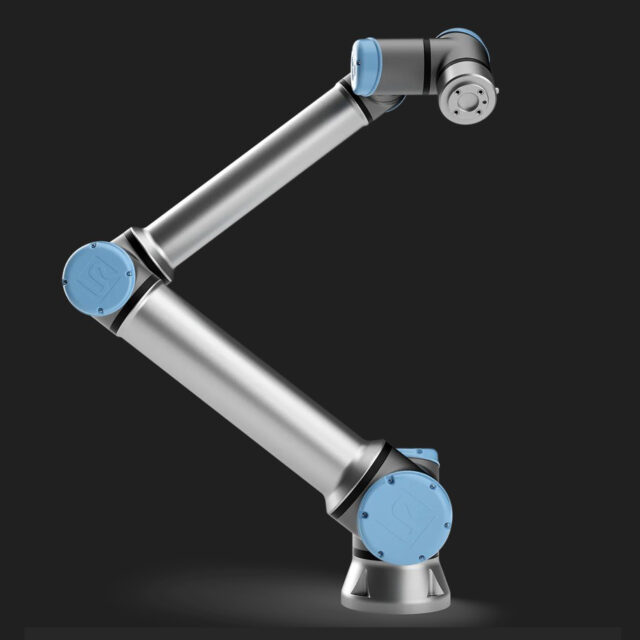

UR10e

Medium-sized, versatile cobot The UR10e is our medium duty industrial collaborative robot that combines both long reach and high payload.…

Flotronic® Barrel Unloading System

The Flotronic Barrel Unloading System combines our unique ‘One Nut’ Sanitary Air-Operated Double-Diaphragm Pump with our Barrel Unloading Skid; perfect…

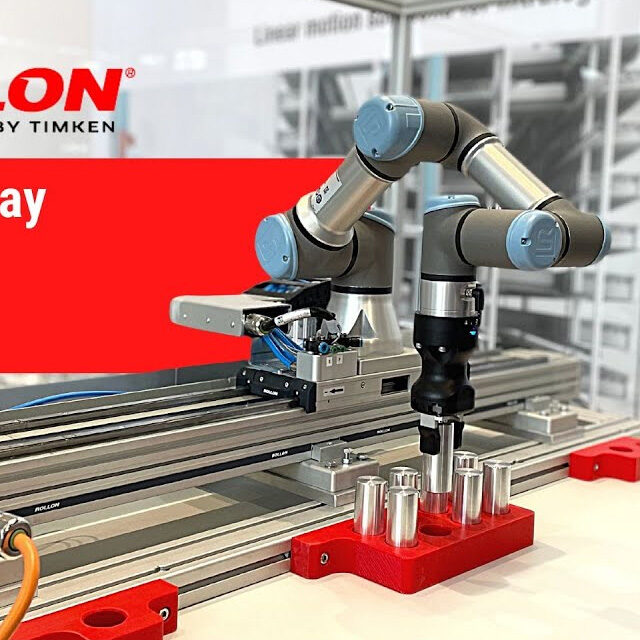

Rollon Cobot Transfer Unit

Rollon CTU or Cobot Transfer Unit is a plug and play solution system that increases UR robots productivity by extending…

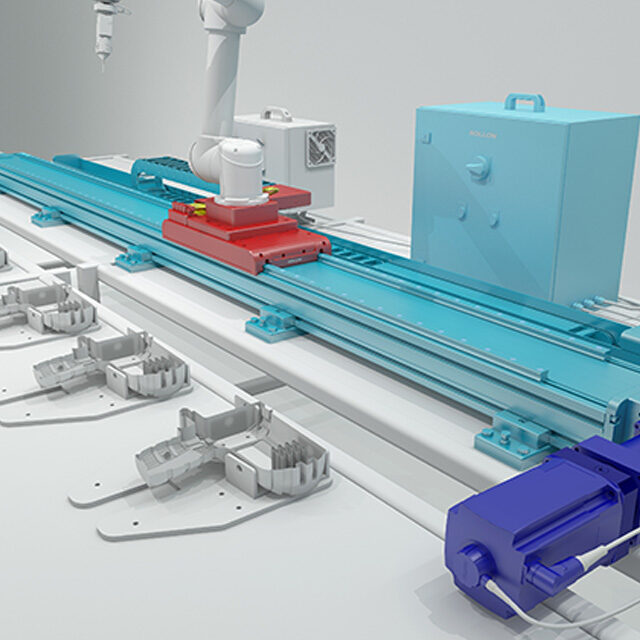

Robot Transfer Unit - Steel Version

With our new RTU (Robot Transfer Unit) from Rollon, you improve the reach of your robots. The RTU is made…

The new UR30 cobot has arrived!

Heavy payload, compact cobot this is the Universal Robots UR30 Building off the same architecture as the UR20, the UR30…

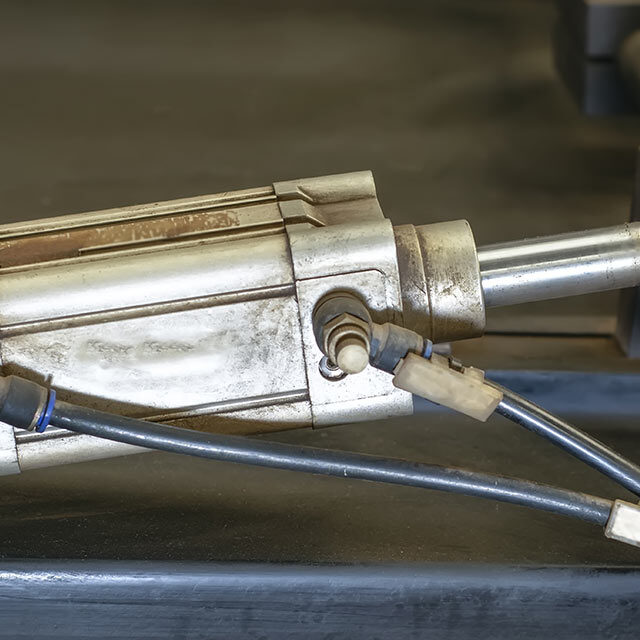

Pneumatic Cylinders with Brand Standard and Custom stroke lengths

What is a Pneumatic Cylinder We know that Pneumatic Cylinders are mechanical devices which produce force by using energy from…

Check out our online store

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Lorem ipsum dolor

Subscribe to our newsletter

Be the first one to find out about our latest products and solutions!

[mc4wp_form id="348"]